Na'urar walda ta Laser ta Hannu

Gajeren bayanin abun ciki

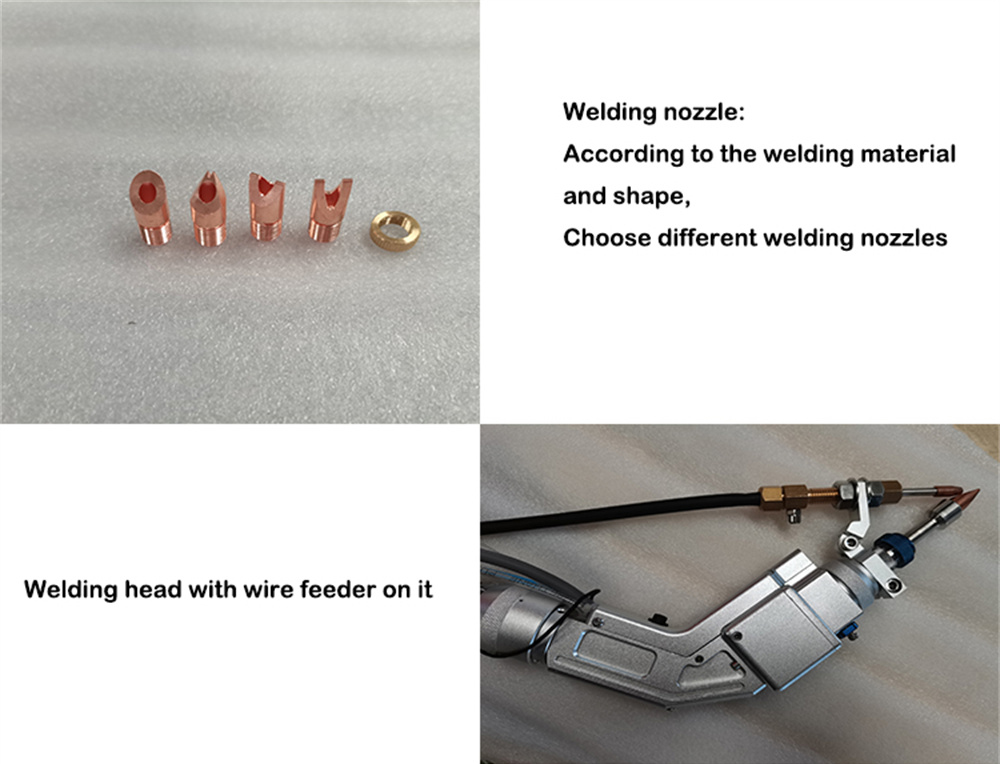

- Akwai hanyoyin walda 6 da nozzles masu yawa don saduwa da buƙatun walda daban-daban; yana da aikin firikwensin tsaro, wanda ke fitar da Laser bayan ya taɓa ƙarfe kuma yana kulle haske ta atomatik lokacin da aka cire shi.

- Na'urar tana sanye da na'urar mai ba da waya ta atomatik, wanda zai iya daidaita sigogi cikin sauƙi kuma ya ba da zaɓi da yawa don

abokan ciniki.

- Akwai hanyoyin walda 6 da nozzles masu yawa don saduwa da buƙatun walda daban-daban; yana da aikin firikwensin tsaro, wanda ke fitar da Laser bayan ya taɓa ƙarfe kuma yana kulle haske ta atomatik lokacin da aka cire shi.

- Dual zazzabi da dual iko, kewaya ruwa kewaye, iya sauri kwantar da ciki bututun rami na waldi shugaban, yayin da sanyaya Laser.

Nuni samfurin

Sigar fasaha

| Sharadi | Sabo | Abubuwan Mahimmanci | Tushen Laser |

| Amfani | Weld Metal | Max. Ƙarfin fitarwa | 2000W |

| Abubuwan da ake Aiwatar da su | Karfe | Cnc Ko A'a | Ee |

| Yanayin sanyaya | Sanyaya Ruwa | Software na sarrafawa | Ruida/Qilin |

| Nisa Pulse | 50-30000Hz | Ƙarfin Laser | 1000w/1500w/ 2000w |

| Nauyi (Kg) | 300 Kg | Takaddun shaida | Ce, Iso9001 |

| Abubuwan Mahimmanci | Fiber Laser Source, Fiber, Handle Laser Weld Head | Mabuɗin Siyarwa | Babban Daidaito |

| Aiki | Karfe Part Laser Welding | Tsawon Fiber | ≥10m |

| Masana'antu masu dacewa | Otal-otal, Shagunan Tufafi, Shagunan Kayayyakin Gini | Abubuwan Mahimmanci | Laser Supply |

| Yanayin Aiki | Buga | Bayan Sabis na Garanti | Tallafin kan layi |

| Diamita Mai Faɗakarwa | 50 μm | Tsawon tsayi | 1080 ± 3nm |

| Bidiyon Fitowar Bidiyo | An bayar | Ana Tallafin Tsarin Zane | Ai, Plt, Dxf, Dwg, Dxp |

| Wuri Na Asalin | Jinan, Shandong | Lokacin Garanti | Shekaru 3 |

Babban Sassan Na'ura

Welding siga ga Laser waldi inji

Kanfigareshan

| Ƙarfin Laser | 1000w | 1500W | 2000W | ||||||

| Kayan walda | Bakin Karfe | Karfe Karfe | Aluminum | Bakin Karfe | Karfe Karfe | Aluminum | Bakin Karfe | Karfe Karfe | Aluminum |

| Kaurin Welding (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Kaurin Welding (Inci) |

|

|

|

|

|

|

|

|

|

| Waya mai daidaitawa | Welding Wire Diamita 0.8-1.6mm | ||||||||

| Weld Seam Bukatun | Filler Waya Welding≤1Mm Swinging Welding ≤15% Na Kaurin Faranti≤0.3Mm | ||||||||

| Nauyin Inji | 220Kg | 220Kg | 300Kg | ||||||

| Girman Injin(Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Layin Bindigan Welding | 10m (The Waya Feed Tube Na Waya Feeder ne 3 Mita Dogon) | ||||||||

| Welding Gun Weight | Nau'in Madubin Jijjiga (Qi Lin): 0.9Kg | ||||||||

| Ƙarfin Na'ura | 7 kw | 9 kw | 12 kw | ||||||

| Harshe Yana Tallafawa | Standard: Sinanci, Turanci, Koriya, Vietnamese, Rashanci Jafananci Da Mutanen Espanya Za a iya Keɓance su | ||||||||

| Voltage Da Mitar | Ma'auni: 380V/50Hz Sauran Wutar Lantarki da Mitar Na Zabi ne | ||||||||

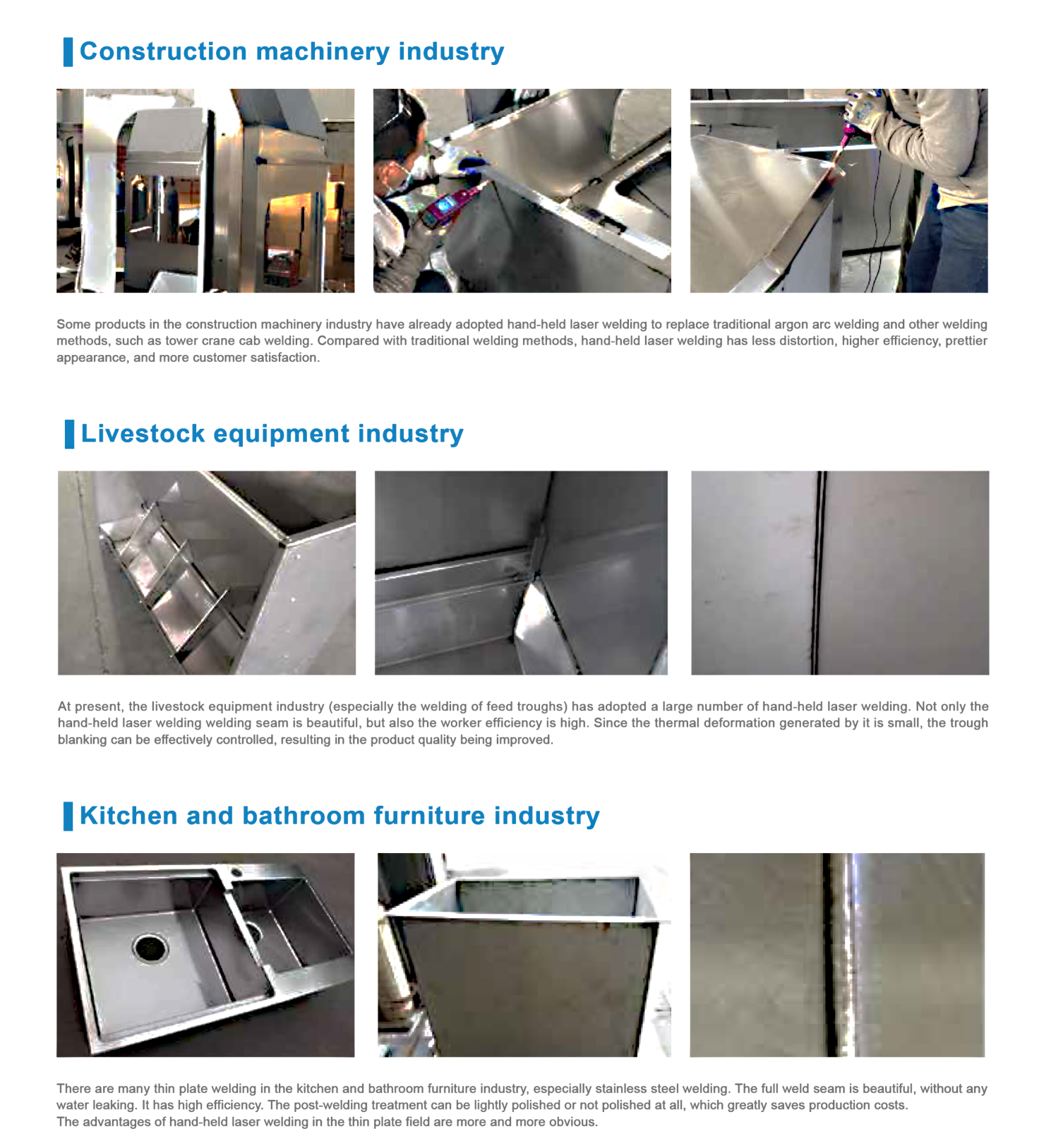

Masana'antar aikace-aikace

Ana amfani da injunan walda na Laser a masana'antar gidan wanka: walda na haɗin bututun ruwa, rage haɗin gwiwa, tees, bawul, da shawa. Gilashi masana'antu: daidai waldi na bakin karfe, titanium gami da sauran kayan a kan zare matsayi, m frame da sauran matsayi na tabarau. Hardware masana'antu: impeller, kettle, rike, da dai sauransu, waldi na hadaddun stamping sassa da simintin gyaran kafa sassa. Laser walda inji ana amfani da ko'ina a cikin mota masana'antu: engine Silinda gaskets, na'ura mai aiki da karfin ruwa tappet hatimin waldi, walƙiya waldi, tace waldi, da dai sauransu.

Amfanin na'urar waldawa ta Laser

1. Wide waldi kewayon: Hannun waldi shugaban yana sanye take da 5m-10m na asali fiber fiber, wanda ya shawo kan iyaka na workbench sarari da kuma za a iya amfani da waje waldi da kuma nesa waldi;

2. Mai dacewa da sassauƙa don amfani: Ana amfani da waldi na Laser na hannun hannu tare da ɗigon motsi, wanda ke da dadi don riƙewa, kuma za'a iya daidaita shi a kowane lokaci, ba tare da buƙatar tashoshi mai mahimmanci ba, kyauta da sassauƙa, kuma ya dace da yanayin yanayin aiki daban-daban.

3. Daban-daban hanyoyin walda: walda a kowane kusurwa za a iya gane: dinki waldi, butt waldi, a tsaye waldi, lebur fillet waldi, ciki fillet waldi, waje fillet waldi, da dai sauransu waldi. Welding a kowane kusurwa za a iya cimma. Bugu da kari, ya kuma iya kammala yankan, waldi da yankan za a iya canzawa da yardar kaina, kawai canza walda bututun ƙarfe zuwa yankan bututun ƙarfe na jan karfe, wanda ya dace sosai.

4. Kyakkyawan sakamako na walda: walƙiya laser na hannu yana da walƙiya mai zafi. Idan aka kwatanta da al'ada waldi, Laser waldi yana da mafi girma makamashi yawa da kuma iya cimma mafi alhẽri waldi sakamako. Matsalolin ganowa, zurfin walƙiya mai girma, isassun narkewa, tsayayye kuma abin dogaro, da ƙarfin walda ya kai ko ma wuce ƙarfen tushe da kanta, wanda injin walda na yau da kullun ba zai iya lamunce shi ba.

5. Ba ya bukatar goge-goge: Bayan walda na gargajiya, ana so a goge wurin walda don tabbatar da santsi ba tauri ba. walda Laser hannun hannu kawai yana nuna ƙarin fa'idodi a cikin tasirin sarrafawa: ci gaba da waldawa, santsi ba tare da ma'aunin kifi ba, kyakkyawa ba tare da tabo ba, da ƙarancin niƙa na gaba.

6. Babu abubuwan da ake amfani da su don walda: A yawancin ra'ayoyin mutane, aikin walda shine " tabarau a hannun hagu da wayar walda a hannun dama ". Duk da haka, tare da na'urar waldawa ta hannu, ana iya kammala waldawar cikin sauƙi, kuma an rage farashin kayan aiki da sarrafawa.

7. Tare da mahara aminci ƙararrawa, da waldi tip ne kawai tasiri a lokacin da canji da aka shãfe a lõkacin da ta shãfe karfe, da kuma haske ne ta atomatik kulle bayan workpiece da aka cire, da kuma tabawa canji yana da jiki zafin jiki firikwensin. Babban aminci, tabbatar da amincin masu aiki yayin aiki.

8. Ajiye kudin aiki: Idan aka kwatanta da waldawar baka, ana iya rage farashin sarrafawa da kusan 30%. Aikin yana da sauƙi kuma mai sauƙi don koyo da sauri don koyo, kuma ƙirar fasaha na mai aiki ba ta da girma. Ana iya ɗaukar ma'aikata na yau da kullun bayan ɗan gajeren horo, kuma suna iya samun sakamako mai inganci cikin sauƙi.