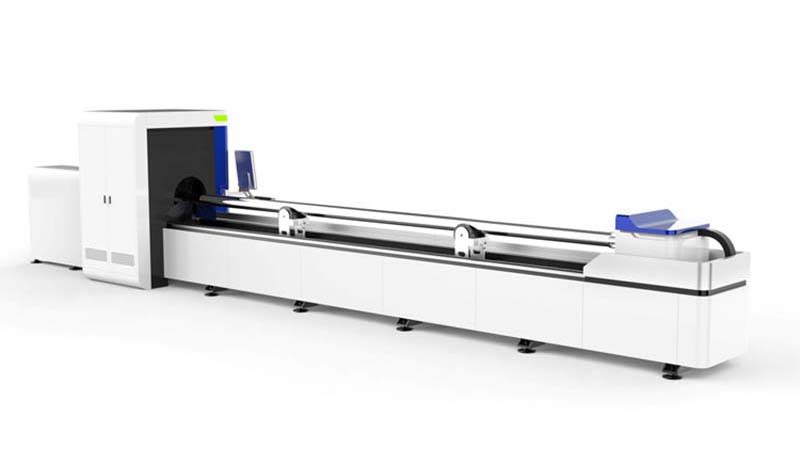

Tare da saurin haɓaka fasahar laser,Laser bututu sabon injiana ƙara amfani da su a masana'antu da yawa. Fitowar kayan yankan bututun Laser ya kawo sauye-sauye na sauye-sauye ga tsarin yankan na masana'antar bututun ƙarfe na gargajiya. The Laser sabon na'ura yana da halaye na high aiki da kai, high dace, da kuma high fitarwa. Don bututu na kayan daban-daban, babu buƙatar maye gurbin ma'aunin gani mai dacewa, kuma babu buƙatar dakatar da tsakiyar hanya. Ya dace sosai don samar da taro.

Don kula da babban aiki na na'ura mai yankan bututun Laser, wajibi ne a kula da kayan aiki akai-akai, don haka ta yaya za a kula da na'urar yankan bututu? Baya ga kula da gadon kayan aiki, kula da chuck yana da matukar muhimmanci. Wadannan shawarwari guda 4 ne don kula da chuck.

1. Don lubrication na chuck, yi amfani da lubricant zuwa chuck akai-akai don tabbatar da cewa kullun na iya samun daidaitattun daidaito yayin motsi. Kula lokacin da ake shafawa. Lubrication da ba daidai ba na iya haifar da chuck na pneumatic ya kasa yin aiki akai-akai lokacin da iska ta yi ƙasa, ƙarfin matsawa ya raunana, daidaiton matsewa ba shi da kyau, lalacewa ba ta da kyau ko makale, don haka kula da aikin lubrication daidai lokacin yin lubrication.

1. Don lubrication na chuck, yi amfani da lubricant zuwa chuck akai-akai don tabbatar da cewa kullun na iya samun daidaitattun daidaito yayin motsi. Kula lokacin da ake shafawa. Lubrication da ba daidai ba na iya haifar da chuck na pneumatic ya kasa yin aiki akai-akai lokacin da iska ta yi ƙasa, ƙarfin matsawa ya raunana, daidaiton matsewa ba shi da kyau, lalacewa ba ta da kyau ko makale, don haka kula da aikin lubrication daidai lokacin yin lubrication.

2. Yi amfani da man shafawa na molybdenum disulfide, yawanci baƙar fata, kuma a saka man shafawa a cikin bututun chuck har sai maiko ya mamaye saman muƙamuƙi ko rami na ciki na chuck. Idan chuck yana aiki a cikin babban sauri na dogon lokaci ko yana amfani da kayan aiki na taimakon oxygen na dogon lokaci, ana buƙatar ƙarin lubrication, kuma dole ne a daidaita yawan lubrication bisa ga ainihin yanayin aiki.

3. Bayan an gama aiki a kowane lokaci, ya zama dole a yi amfani da bindigar iska mai ƙarfi don magance ƙurar ƙura a kan chuck kanta da kuma slideway. Ana ba da shawarar tsaftace jaws na chuck kowane watanni 3-6 don kiyaye farfajiyar tsabta da mai mai. Bincika ko sassan sun karye kuma sun sawa, kuma a maye gurbin su idan lalacewa yana da tsanani. Bayan dubawa, ya kamata a lubricated jaws da kyau da kuma shigar da kafin amfani.

4. Na musamman workpieces ko maras misali workpieces bukatar da za a clamped da kuma sarrafa tare da takamaiman chucks. A misali Laser bututu sabon chuck ya dace da symmetrical da rufaffiyar tube siffofi. Idan kun yi amfani da shi da ƙarfi don matsawa marasa daidaituwa ko baƙon kayan aiki, zai haifar da rashin daidaituwa; idan karfin samar da iska na chuck ya yi yawa, chuck din zai kasance a karkashin babban matsi ko kuma bayan rufewa Har ila yau, chuck din yana danne kayan aiki, wanda zai rage rayuwar chuck kuma ya haifar da matsaloli irin su wuce gona da iri.

5. Hana ɓoyayyen ƙarfe na chuck daga tsatsa. Rigakafin tsatsa wani mahimmin batu ne. Tsatsa na chuck zai rage karfin matsawa kuma ba zai iya matsa kayan aikin ba, wanda ke da matukar tasiri ga daidaito da ingancin samarwa.

Hanyar da ke sama ita ce hanya mai mahimmanci don kula da na'urar yankan bututun Laser. Tabbas, yin amfani da tsattsauran ra'ayi na ma'aikacin da daidaitattun matakan aiki na ma'aikata suma mahimman abubuwan ne don kiyaye aikin injin yanke bututu.

Lokacin aikawa: Janairu-19-2023