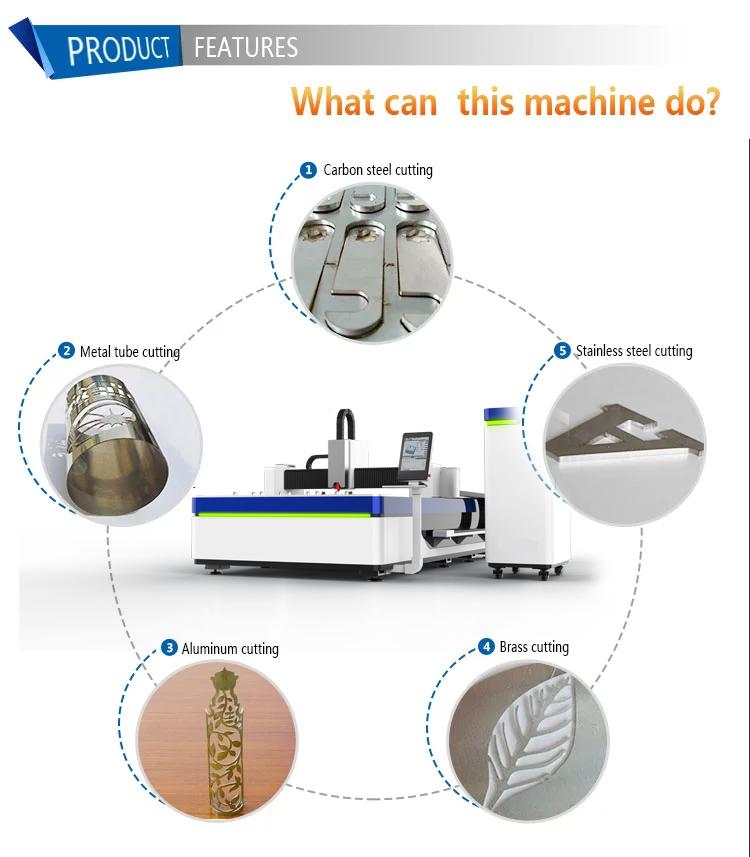

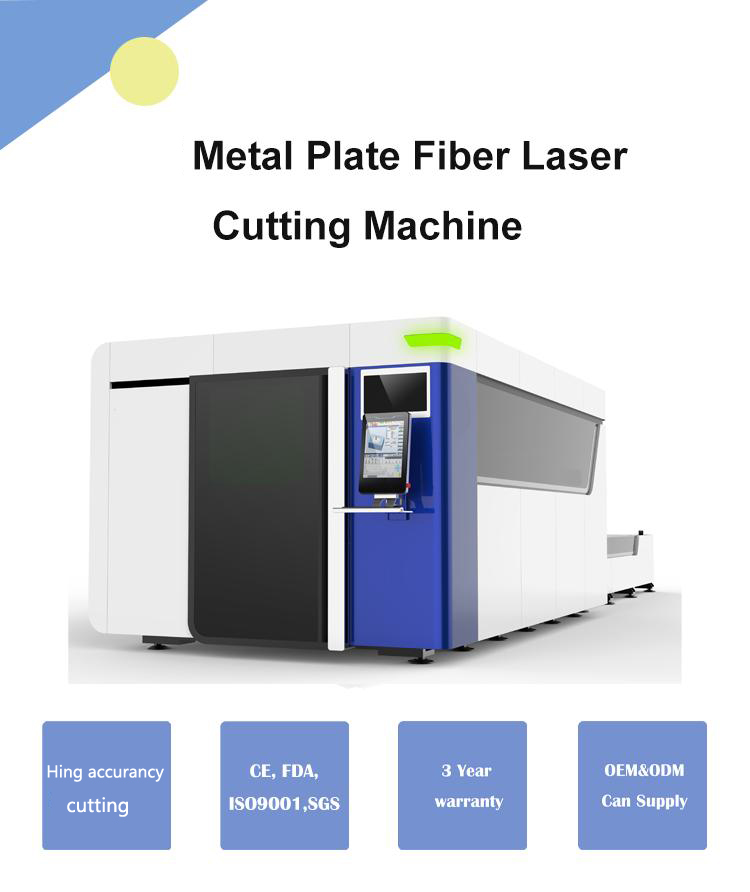

Injin Yankan Laser Gabaɗaya

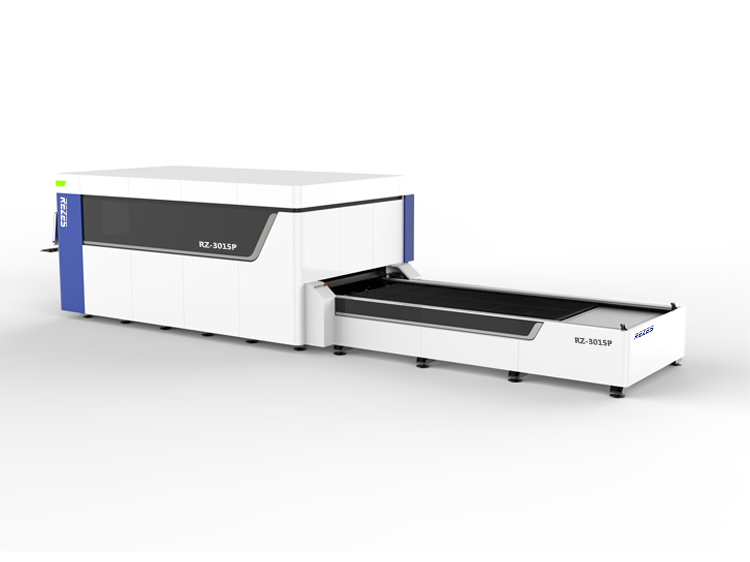

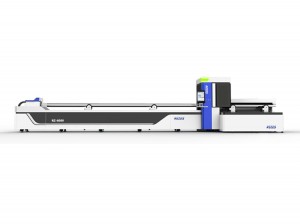

Nuni samfurin

Sigar fasaha

| Aikace-aikace | Laser Yankan | Abubuwan da ake Aiwatar da su | Karfe |

| Yanke Yanke | 1500mm*3000mm | Nau'in Laser | Fiber Laser |

| Software na sarrafawa | Cypcut | Laser Head Brand | Raytools |

| Servo Motor Brand | Yaskawa motor | Rahoton Gwajin Injin | An bayar |

| Ana Tallafin Tsarin Zane | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC ko a'a | Ee |

| Mabuɗin Siyarwa | Babban daidaito | Nauyi | 4500kg |

| Yanayin Aiki | atomatik | Matsayi Daidaito | ± 0.05mm |

| sake sakawa daidaito | ± 0.03mm | Kololuwar Haɗawa | 1.8G |

| Masana'antu masu dacewa | Otal-otal, Shagunan Kayayyakin Gini, Shuka Masana'antu | Sassan huhu | SMC |

| Yanayin Aiki | ci gaba da igiyar ruwa | Siffar | Cikakken murfin |

| Gudun Yankewa | dangane da iko da kauri | Software na sarrafawa | Tubepro |

| Yanke Kauri | 0-50mm | Brand Guiderail | HIWIN |

| Kayan lantarki | schneider | Lokacin garanti | shekaru 3 |

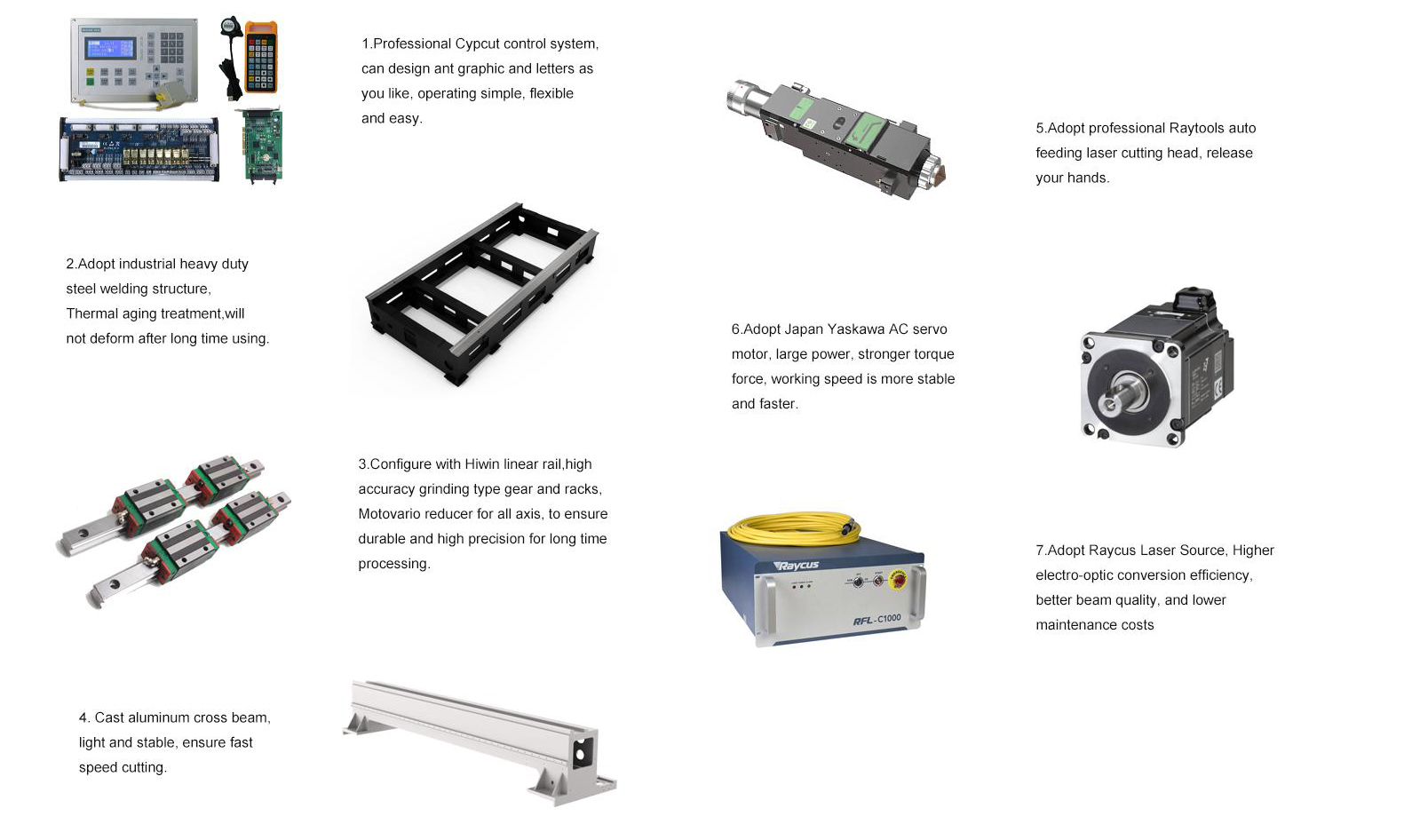

Kayan inji

Bidiyon Inji

Injin Yankan Laser Gabaɗaya

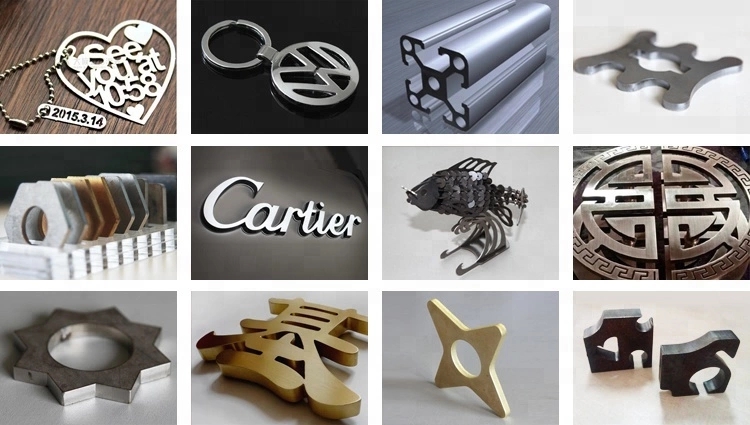

Yanke samfurori

Aikace-aikace

1. Masana'antar kera motoci

Ana amfani da na'urorin yankan Laser a cikin murfin mota na gaba, karfen mota, bututun shaye-shaye, da sauransu, kuma suna buƙatar sarrafa su bayan ƙirƙirar kusurwoyi masu yawa ko burrs. Idan ana amfani da aikin hannu, yana da wahala a cimma daidaitattun daidaito da daidaito da ake so.

2. Masana'antar ado

Masana'antar kayan ado tana buƙatar amfani da zane-zane masu yawa, kuma na'urar yankan Laser na iya saduwa da aikace-aikacen wannan masana'antar tare da saurin yankewar sauri da yanke sassauƙa, kuma ya shahara sosai tsakanin kamfanonin ado. Bayan zana zane-zane masu dacewa, ana iya yanke shigo da dannawa ɗaya.

3.Masana'antar talla

Fiber Laser Cutting Machines ana amfani da su sosai a masana'antar Billboard, Talla, Alamu, Alamu, Haruffa na Karfe, Haruffa LED.

4.Kayan gida da masana'antar dafa abinci

Kayan gida da kayan dafa abinci an yi su ne da faranti na sirara. Kafin aiwatar da stamping da zane, ana amfani da injin yankan fiber Laser don aiwatar da samfuran don haɓaka sabbin samfuran da sauri. Gudun yankan kayan aiki na Laser yana da sauri, wanda ya inganta ingantaccen aiki. A lokaci guda, kayan aiki na Laser yana da madaidaicin yankan, wanda ke inganta yawan amfanin ƙasa na kewayon hoods da na'urori masu ƙonewa. Don wasu samfura masu siffa na musamman, na'urorin yankan fiber Laser suna da fa'idodi na musamman, gami da kabad ɗin rarraba wutar lantarki, ɗakunan ajiya, da sauransu, waɗanda duk daidaitattun samar da faranti na bakin ciki ne kuma suna buƙatar inganci. Yin amfani da na'urorin yankan Laser na iya inganta ingantaccen aiki sosai.

5.Agricultural machinery Industry

Akwai nau'ikan nau'ikan nau'ikan nau'ikan kayan aikin kayan aikin noma, kuma ana sabunta su cikin sauri. Sassan sarrafa ƙarfe na gargajiya na kayan injuna na kayan aikin gona yawanci suna amfani da hanyar naushi, wanda ke cinye ƙira da yawa. Idan har yanzu sarrafa sassan ya kasance a cikin hanyar gargajiya, zai hana musanya samfuran da gaske. A m aiki halaye na Laser suna nuna. Sarrafa Laser na iya gane yanke nau'ikan faranti daban-daban tare da taimakon software na shirye-shirye. Yin amfani da Laser aiki ba kawai yana da sauri aiki gudun, high dace, da kuma low cost, amma kuma ba ya bukatar maye gurbin molds ko kayan aiki, gajarta samar da shirye-shiryen lokaci. Hakanan zai iya ci gaba da tafiya lokacin da aka sabunta samfurin, kuma ana iya yanke sabon salo ta hanyar sake zana da shirye-shirye. Abu ne mai sauki don gane ci gaba da aiki, da Laser katako transposition lokaci ne takaice, da kuma samar da yadda ya dace ne high. Ana iya shigar da kayan aiki iri-iri a madadin. Lokacin da aka sarrafa kayan aiki, za a iya cire sassan da aka kammala kuma ana iya shigar da kayan aikin da za a sarrafa don gane aiki a layi daya.

6.Construction inji masana'antu

A cikin masana'antun masana'antu, fiber Laser yankan madauwari ramukan za a iya amfani da idan dai diamita na workpiece madauwari rami ne mafi girma fiye da ko daidai da farantin kauri, da roughness da diamita bukatun ne a cikin garanti iya aiki na yankan na'ura lokacin da fuskantar wani takamaiman farantin kauri. Laser kai tsaye yana yanke kayan, yana kawar da tsarin hakowa da inganta ingantaccen samar da aiki. Ga wasu workpieces da yawa ramuka, da tabo aiki na fiber Laser sabon na'ura da ake amfani da su domin sanin matsayi na ramin, wanda ceton lokaci domin saka ramin ga m rami hakowa tsari, da kuma ceton samar da kudin na hakowa samfuri, wanda ba kawai inganta samar da yadda ya dace, amma kuma inganta daidaito na samfurin.