一. Gabatarwar samarwa:

JCZ dual-axis babban-tsayi tsaga yana amfani da JCZ dual-extended axis control board don cimma alamar splicing fiye da girman madubin filin.Ana ba da shawarar yin amfani da tsari sama da 300 * 300, saboda babban tsari yana cika ta hanyar ƙananan madubin filin splicing da alama, don haka akwai fa'idodin ƙarfin haske mai ƙarfi, zurfin alamar alama, da sauransu, da mai da hankali mai sauƙi, amma yana buƙatar. high inji madaidaici, don haka da debugging tsari ne m.

二. Shigar da injin:

Domin za a cire wasu sassa yayin aikin isarwa, kuna buƙatar shigar da su da kanku bayan karɓar na'ura.Abin da kuke buƙatar shigarwa ya haɗa da ginshiƙi da hanyar gani.Don hanyar shigarwa, koma zuwa na'ura mai alama na yau da kullun.

三.Gwajin gudu:

Bayan an shigar da duk kayan aikin, ana buƙatar gwaji mai sauƙi guda ɗaya, gami da fitar da haske da gwaje-gwajen motsi na kowane axis.

1. Gwajin Gudu:

Bayan shigarwa, mataki na farko shine gyara kuskuren yau da kullum kamar gwajin haske da gyara murdiya.

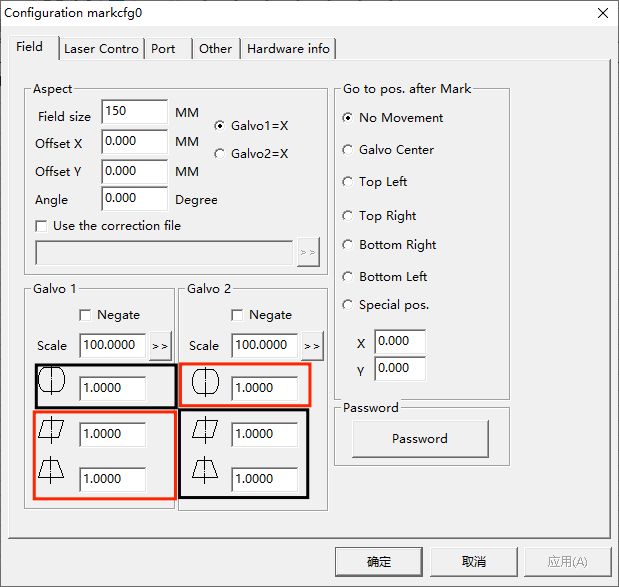

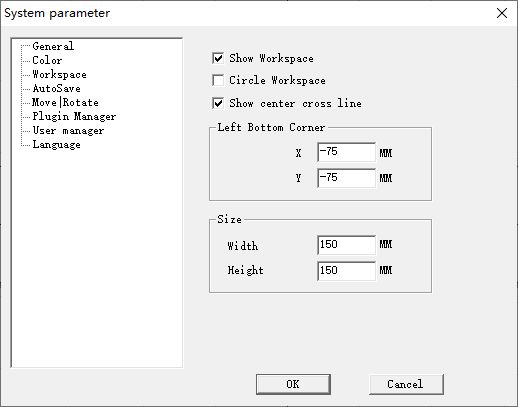

Cika matsayi na wurin tsakiya da girman bisa ga girman ruwan tabarau na filin.Danna kan sigogi a ƙasan daidaitaccen dubawa, kuma cika gwargwadon girman kewayon ruwan tabarau na filin.

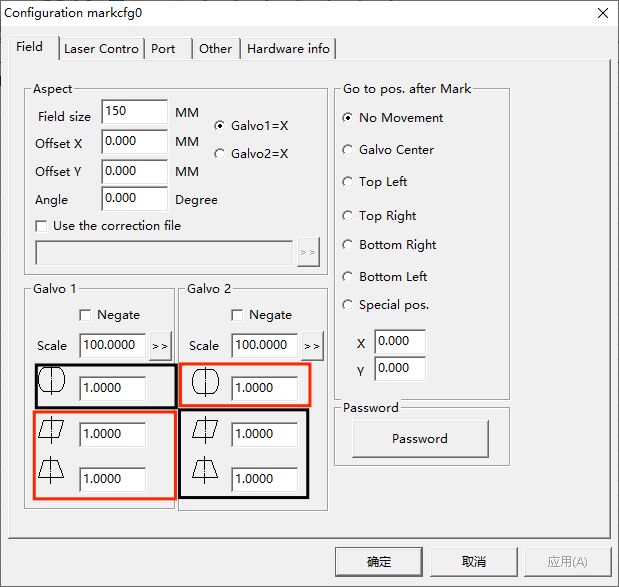

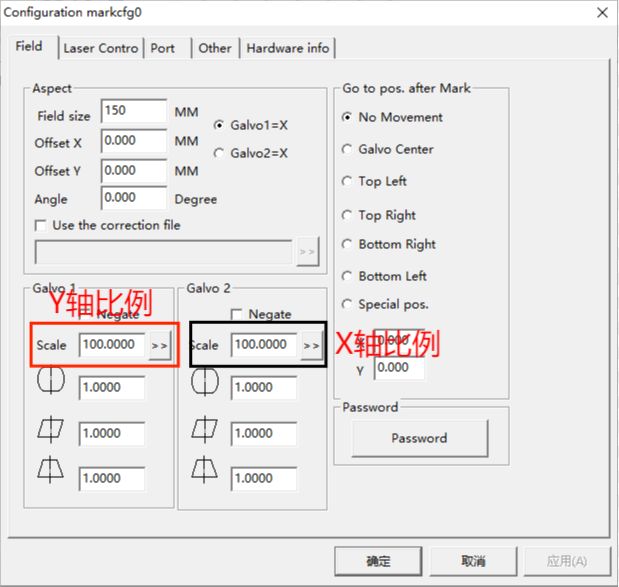

Gyaran ma'auni, yiwa akwatin mafi girma alama bisa ga kewayon alamar, sannan yi masa alama.Bayan aunawa, cika ma'auni mai dacewa bisa ga ainihin ƙimar ma'auni.Misali, axis X shine 150mm, kuma ainihin ma'auni shine 152mm.Cika wannan adadi mai zuwa, kuma axis Y shine dalili guda har sai ya yarda.

Sa'an nan kuma cika ma'auni na gyaran gyare-gyare bisa ga ma'auni na ainihin ma'aunin nakasar murabba'i, kamar yadda aka nuna a cikin adadi, ma'aunin nakasar Y-axis suna cikin akwatin ja, kuma ma'aunin nakasar X-axis suna cikin akwatin baki.

Firam ɗin da aka yiwa alama murabba'i ne, ba tare da lalacewa ba kuma ba tare da gefuna na tunani ba.

2. Daidaita axis guda biyu:

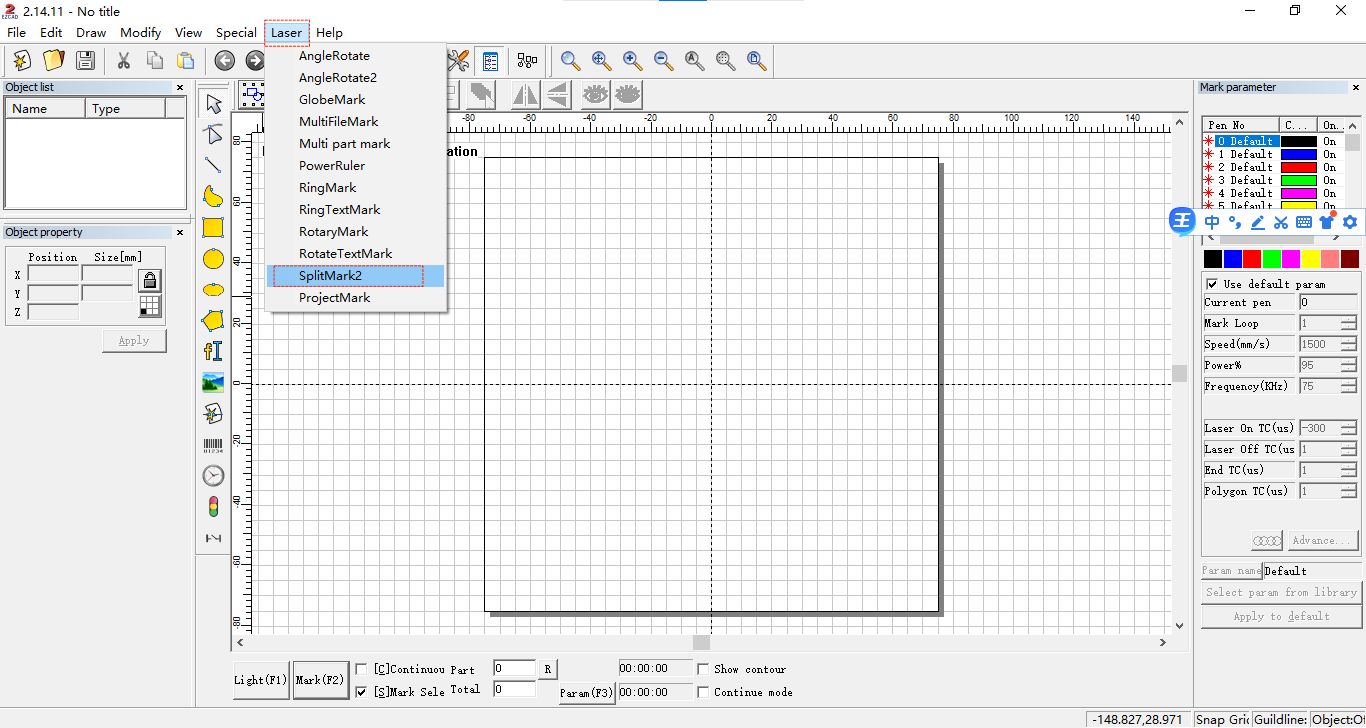

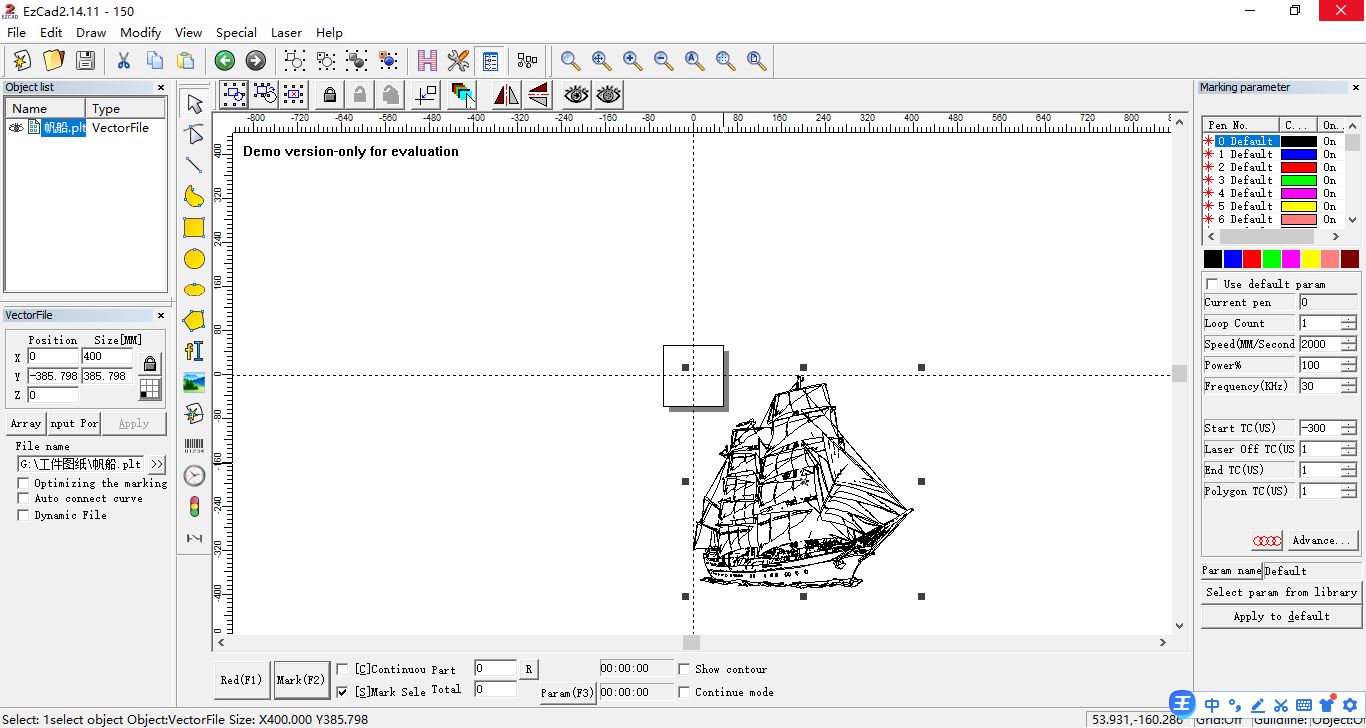

A saman software ɗin, zaɓi Laser -SplitMark2 don shigar da shafin aikin SplitMark.

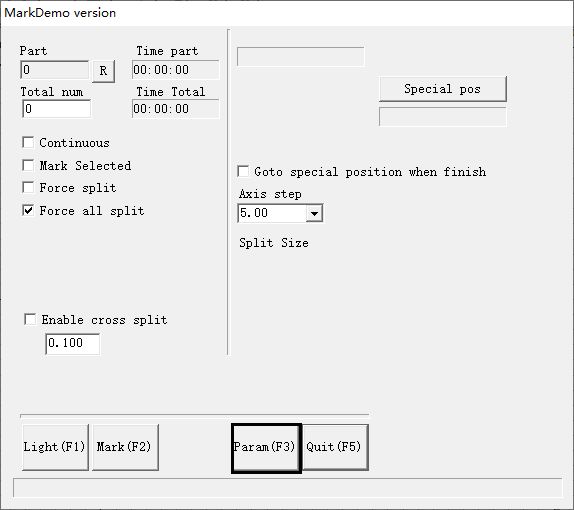

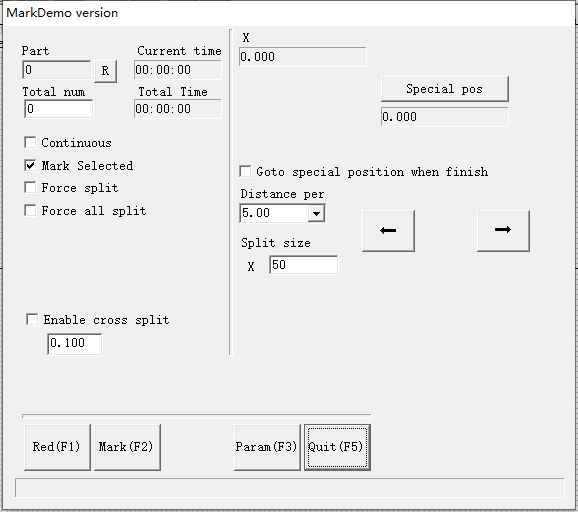

Wannan shafin aiki ne na SplitMark.Yanzu ba a bude gatari biyu na waje ba.Danna "F3" da ke ƙasa don shigar da saitin axis na waje.

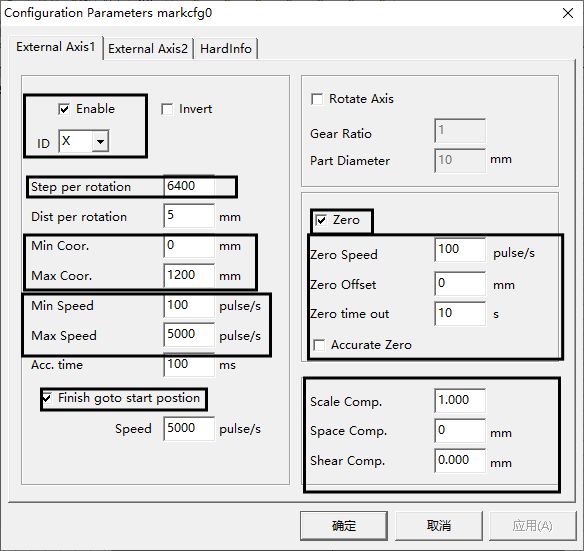

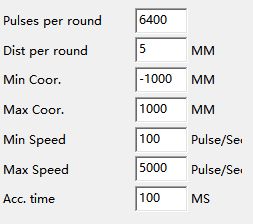

Ɗauki saitin waje na X a matsayin misali.Bayan buɗewa, kuna buƙatar bincika maɓallin kunnawa, zaɓi X azaman ID, sannan ku cika Pulses kowane zagaye da ke ƙasa don dacewa da ainihin saitin tuƙi, in ba haka ba za a sami matsaloli kamar matakan da suka ɓace ko ƙarancin motsi.Mafi ƙarancin Coor shine 0, kuma an cika matsakaicin nisa gwargwadon girman injin ɗin.

Saitin sifili yana da jihohi uku, Wannan shi ne gaba sifili koma, bayan sifili batu da aka saita, da shugabanci komawa zuwa sifili batu gaba.Wannan jihar ita ce yanayin dawowar sifili.Bayan saita sifilin sifilin, motar ta koma wurin sifilin.A cikin wannan jiha, babu maki sifili, kuma motar ba ta komawa sifili.

Bayan saita alkiblar dawowar sifili na kowane axis don zama daidai, wajibi ne a daidaita daidaitattun daidaiton kowane axis.Hanyar daidaitawa ita ce zana madaidaiciyar layi na 100mm, 200mm, da 300mm, sannan a yi alamar tsaga, auna layin alamar bayan yin alama, da kwatanta sakamakon., bisa ga ainihin ma'auni, daidaita Dist a kowane zagaye har sai an daidaita

tsayin manufa ya yi daidai da tsayin da aka yi alama.

Bayan an daidaita nisan mataki, ana buƙatar daidaita tasirin ɗinki.Har yanzu zana layin kwance tare da tsawon 100mm, kuma sanya layin a cikin ƙananan kusurwar dama na duk kewayon aiki.

Sannan danna SplitMark, saita girman alamar tsaga, saita shi zuwa 30mm, fara alama, sannan duba tasirin.

Idan tasirin splicing ya kasance kamar yadda aka nuna a cikin adadi, yana nufin cewa ruwan tabarau na filin ba daidai ba ne da axis X, kuma kusurwar galvanometer ko axis X yana buƙatar daidaitawa har sai an yi lebur.Haka yake ga daidaitawar Y-axis.Idan an daidaita galvanometer don zama daidai da axis X a baya, sannan wannan matsala ta faru yayin daidaitawar Y-axis, kuna buƙatar daidaita daidaituwa tsakanin axis X da Y-axis har sai an gama daidaitawa. .

3. Alamar farawa:

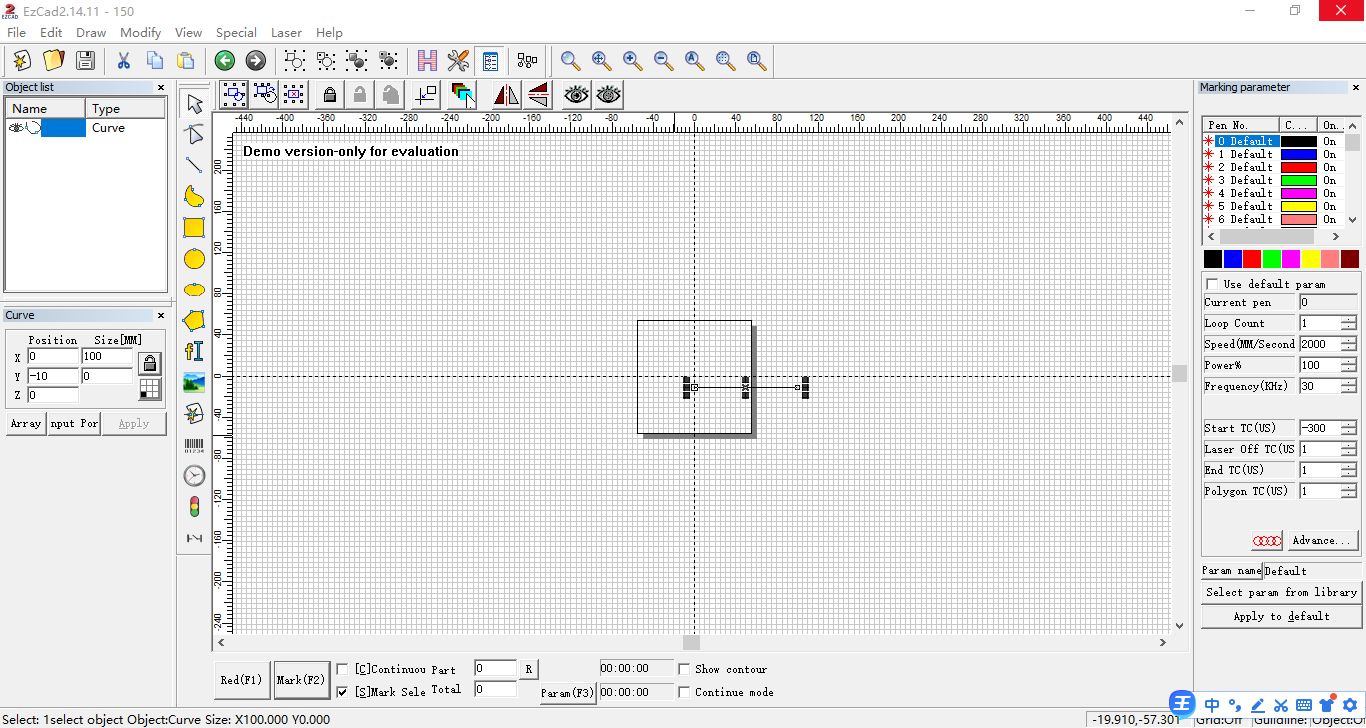

Bayan daidaita tasirin splicing, zaku iya fara yin alama.Yin alama yana buƙatar sanya ƙirar da za a yi alama a cikin ƙananan kusurwar dama na kewayon aiki.Kamar yadda aka nuna a cikin adadi, kuma kewayon jadawali baya wuce ma'anar sifili da matsakaicin iyakar axis XY.

Bayan sanya hoton, danna SplitMark2, kuma bayan saita girman tsaga, zaku iya fara yin alama.

Idan matsalar dinki ta sake faruwa yayin aiwatar da alamar, da fatan za a maimaita aikin da ke sama.

Lokacin aikawa: Fabrairu-23-2023